In Pakistan, the adoption of solar energy is growing rapidly due to rising electricity costs and frequent power outages. While most of the attention goes to solar panels, inverters, and batteries, one component that often gets overlooked is the solar panel mounting structure . This structure is critical—it determines how securely and efficiently your solar panels will perform over the next 20–25 years.

Whether it’s a residential rooftop in Lahore, a commercial building in Karachi, or a ground-mounted solar farm in Bahawalpur, the choice of mounting system directly affects your system’s output, durability, and maintenance costs. Pakistan’s diverse geography and climate conditions—from coastal humidity to high-altitude snow—make it essential to choose the right type and material for mounting.

Incorrect mounting can lead to system inefficiencies, physical damage during storms, and reduced energy output. Unfortunately, many installers use substandard materials or skip proper engineering checks, which compromises system performance and safety.

To make a solar investment truly reliable and long-lasting, understanding the various types of mounting structures, materials available, and best practices for installation is essential.

Solar Panel Mounting Structure in Pakistan – Types, Materials, and Best Practices

In this guide, we will explain everything you need to know about solar panel mounting structures in Pakistan, including their types, materials, use cases, and proven installation practices.

What Is a Solar Panel Mounting Structure?

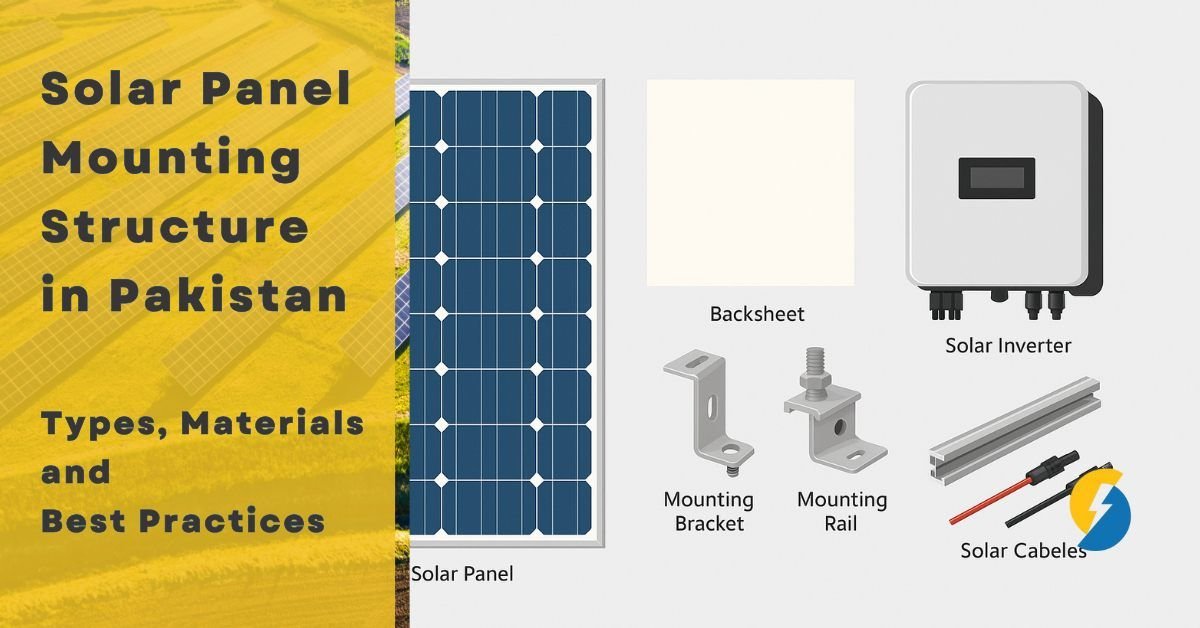

A solar panel mounting structure is the physical framework used to support and hold solar panels securely in place. Its main purpose is to position the panels at the correct angle and orientation to maximize sunlight exposure throughout the day. Without a proper mounting system, solar panels cannot function efficiently or safely.

These structures can be installed on rooftops, open land, poles, or specially designed platforms. They come in various designs, such as fixed-tilt, adjustable-tilt, ground-mount, and solar tracking systems, depending on the installation type and energy needs.

In addition to structural support, mounting systems also provide protection against environmental factors like wind, rain, and dust. They are typically made from durable materials such as galvanized steel, aluminum, or stainless steel to ensure long-term reliability and corrosion resistance.

A well-designed mounting structure not only ensures panel stability but also plays a vital role in the overall lifespan and energy output of the solar system. It should be engineered to withstand local weather conditions, particularly wind speeds, seismic activity, and temperature changes.

In short, the mounting structure is the foundation of any solar installation, supporting performance, safety, and return on investment. Lets discuss it further in detail.

Types of Solar Panel Mounting Structures in Pakistan

FAQ: What are the main types of mounting structures used in solar installations across Pakistan?

There are several types of solar mounting structures available in Pakistan, chosen based on location, usage, and environmental conditions. Each serves specific needs and varies in cost and installation method.

Table: Types of Solar Panel Mounts in Pakistan

| Type | Description | Usage |

|---|---|---|

| Fixed Rooftop Mount | Installed at a permanent angle on rooftops | Residential, small commercial |

| Adjustable Tilt Mount | Angle can be changed manually per season | Commercial, efficient setups |

| Ballasted Mount | Non-penetrating, weighted down by concrete blocks | Rented buildings, flat roofs |

| Ground Mount | Installed directly into the ground with strong frames | Rural and large-scale setups |

| Pole Mount | Mounted on vertical poles, raised from the ground | Off-grid, small remote setups |

| Solar Tracker System | Follows sun path to increase efficiency | Utility-scale solar plants |

Common Materials Used in Mounting Structures in Pakistan

FAQ: Which materials are commonly used for solar mounting in Pakistan?

Materials vary by climate and budget. The right material ensures long-term stability and corrosion resistance.

List of Common Materials:

- Galvanized Steel:

- Widely used due to strength and affordability.

- Rust-resistant due to zinc coating.

- Aluminum:

- Lightweight and rust-proof.

- Ideal for rooftops and areas with high humidity.

- Stainless Steel:

- Highly durable and corrosion-resistant.

- Suitable for coastal areas.

- Mild Steel with Paint:

- Less expensive, needs frequent repainting.

- Suitable for temporary or low-budget setups.

Table: Material Comparison

| Material | Strength | Corrosion Resistance | Cost | Best Use |

| Galvanized Steel | High | Medium | Moderate | Commercial, ground-mount |

| Aluminum | Medium | High | High | Rooftop installations |

| Stainless Steel | High | Very High | High | Coastal, industrial zones |

| Mild Steel | Medium | Low | Low | Temporary, indoor use |

Mounting Techniques and Best Installation Practices

FAQ: What are the key practices for installing solar panel structures in Pakistan?

To ensure durability and optimal performance, correct installation methods must be followed.

List of Best Practices:

- Site Assessment:

- Check wind pressure, sunlight availability, roof or soil strength.

- Proper Tilt Angle:

- Panels should ideally be tilted based on the location’s latitude (25-35 degrees).

- Secure Anchoring:

- Use chemical or mechanical fasteners depending on the rooftop material.

- Wind Load Consideration:

- Design structures to resist wind speeds up to 150 km/h.

- Corrosion Control:

- Separate dissimilar metals to prevent galvanic corrosion.

- Spacing and Layout:

- Allow space for airflow and maintenance access.

Cost Analysis: Mounting Structures in Pakistan

FAQ: How much do solar panel mounting structures cost in Pakistan?

Cost depends on material type, design complexity, and installation location.

Table: Approximate Cost by Type (per kW)

| Mount Type | Material Used | Approx. Cost (PKR) |

| Fixed Rooftop Mount | Aluminum/Steel | 6,000 – 8,000 |

| Adjustable Tilt Mount | Aluminum | 9,000 – 12,000 |

| Ballasted Mount | Steel/Concrete | 7,000 – 9,000 |

| Ground Mount | Galvanized Steel | 10,000 – 14,000 |

| Pole Mount | Steel | 8,000 – 11,000 |

| Tracker System | Motorized Steel | 18,000 – 22,000 |

Local Manufacturing vs Imported Structures

FAQ: Should you use locally made or imported mounting structures?

Both have their advantages depending on budget, availability, and quality control needs.

List Comparison:

Local Structures:

- Pros:

- Lower cost.

- Easier customization.

- Shorter delivery time.

- Cons:

- Variable quality.

- Limited standardization.

Imported Structures:

- Pros:

- Higher quality standards.

- Durable and pre-tested.

- Cons:

- Higher costs due to taxes and logistics.

- Delayed shipping.

Recommendation: For commercial or critical installations, go for imports. For residential or small-scale, quality local options are viable.

Common Challenges in Pakistan’s Solar Mounting Scene

FAQ: What are the common problems faced during installation and usage?

Installers and users face several challenges that impact system performance and longevity.

Top Challenges:

- Substandard Materials:

- Low-quality steel or poor galvanization.

- Improper Tilt Angles:

- Fixed structures often ignore geographic angle alignment.

- Inexperienced Installers:

- Lack of skilled workforce affects structural integrity.

- Ignoring Local Conditions:

- Wind zones and soil types are often not considered.

- No Maintenance Plans:

- Rust or structural damage goes unnoticed until performance drops.

Best Practices to Follow

FAQ: What are the essential practices to ensure a successful and long-lasting solar structure?

Following these practices helps ensure better performance and safety:

Checklist of Best Practices:

- Conduct site surveys before starting.

- Select material based on environmental exposure.

- Verify supplier certifications (ISO, IEC, TÜV).

- Train technicians and supervise installation.

- Use anti-corrosion treatments.

- Tighten bolts and inspect frames yearly.

Table: Installation Do’s and Don’ts

| Do’s | Don’ts |

| Use corrosion-resistant parts | Mix metals without insulation |

| Align panels to true south | Ignore wind and roof pressure data |

| Perform structural testing | Use unverified suppliers |

Final Words

In Pakistan’s rapidly expanding solar market, mounting structures play a central role in the reliability and efficiency of any solar energy system. Whether installed on rooftops, the ground, or on poles, these structures must be selected and installed with care, considering climate conditions, material quality, and installation best practices.

The use of galvanized steel, aluminum, or stainless steel depends heavily on environmental factors such as humidity and wind pressure. Local manufacturing offers budget-friendly options, while imported systems may deliver higher standards in durability and design. The choice between the two should align with the system’s purpose and long-term goals.

Challenges such as poor workmanship, inadequate materials, or improper tilt angles can compromise both performance and lifespan. Adopting proven practices—like site assessments, certified materials, and annual maintenance—can greatly reduce system failures. As Pakistan continues to adopt solar solutions at a national scale, having a clear understanding of solar mounting systems is not just helpful—it’s essential.

This guide provides the insights you need to make informed, practical, and cost-effective decisions about solar panel mounting structures in Pakistan.